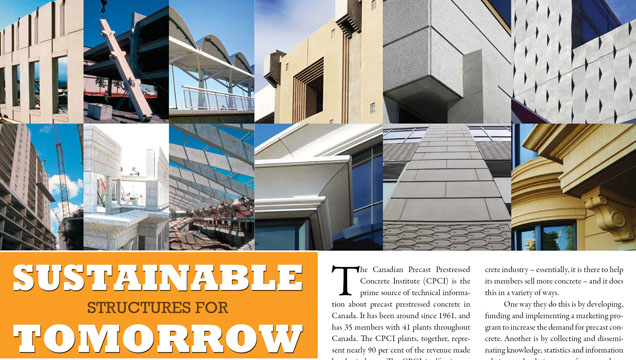

Sustainable structures for tomorrow

The Canadian Precast Prestressed Concrete Institute (CPCI) is the prime source of technical information about precast prestressed concrete in Canada. It has been around since 1961, and has 35 members with 41 plants throughout Canada. The CPCI plants, together, represent nearly 90 per cent of the revenue made by the industry. The CPCI itself exists to stimulate and advance the interests and general welfare of the precast prestressed concrete industry – essentially, it is there to help its members sell more concrete – and it does this in a variety of ways.

One way they do this is by developing, funding and implementing a marketing program to increase the demand for precast concrete. Another is by collecting and disseminating knowledge, statistics and information relating to the design, manufacture and use of precast concrete. Another still is by managing their CPCI Certification program, which establishes industry standards of design and production for precast and prestressed concrete.

The Institute itself has only four staff members. “We’re a relatively small organisation, but we seem to get a lot done,†says Brian Hall, the Managing Director of Sustainability and Business Development for CPCI.

Hall himself is from the IT Industry, and has taught Economics and Communications at the University of Ottawa. At one point, he was actually retired, but an associate pointed him in the direction of CPCI and thirteen years later he is still there.  “I think I’ve stayed because it’s a very good industry with extremely nice people to work with, and it’s kind of in my blood now,†he says.

The product CPCI exists to support is an underrated one, Hall says, and can be used for a large variety of projects. It can be used to build condos, parking garages, bridges, big box stores – among much more – and it has gained traction in all those markets for a few very good reasons. Firstly, precast concrete is made in a factory, so the quality is better than concrete made on a job site. Secondly, a precast project can be erected very quickly.

“If you were doing a bridge out in the middle of a highway somewhere and you’re pouring concrete, you have to wait a week for it to cure before you pour the next section,†Hall says. “With precast concrete, the pieces are already cured, they come to the jobsite, and they go together like Lego. It’s amazing how fast we can actually put buildings up. The speed of precast is unmatched within the marketplace.â€

The next generation

One of CPCI’s main focuses is reaching out to the next generation of concrete workers. They are involved in a number of initiatives in that aim, such as their Big Beam Project for engineering students, as well as their Architecture Design Contest – both of which are available all over Canada. “We also have something else we’re really proud of that’s for everybody, but really directed at students, which is National Precast Day,†Hall says.

National Precast Day, which CPCI has conducted for 14 years now, actually takes place over the course of a week, the first of October. During that week, CPCI arranges for 12 to 15 plants to invite everyone in the building industry – students, professors, engineers, et cetera – to come out and take a tour and observe how precast is made. This gives CPCI an outlet to talk about the advantages of precast concrete, such as the speed of construction, the quality of the product itself, and the sustainability benefits. “It’s a really big education vehicle that we use,†Hall says. “Students really learn a lot, because there’s nothing like seeing something made right in front of you.â€

In addition, CPCI offers a whole range of educational materials such as textbooks and CDs. They are also happy to arrange for lecturers to appear at any university that requests it. “The students are the future of the construction industry,†Hall says. “We feel it’s very, very important to educate them.â€

CPCI certified

Another one of CPCI’s central services is their certification program, which they are constantly improving. Today’s CPCI certification program is actually their second. Their first started in 1963, but only ran for a few years before they realised they did not have the proper manpower to manage it. At that point, the Canadian Standards Association (CSA) took it off their hands. “We were quite happy with that other program probably for the first 30 years or so,†Hall says. In the last 20 years, however, the Institute began to feel that the CSA had been putting undue focus on documentation, and not enough focus on helping plants make better precast.

“At a meeting, I asked one question one time our CSA representative,†Hall says. “I asked if he’d ever decertified a plant in Canada, and he said ‘no’. I thought that was ridiculous. So the association felt, for the betterment of the industry, that we should start our own program again.â€

Today both programs co-exist, but CPCI’s is much tougher, and thus a more valuable indicator of quality. The province of Alberta even conducted an audit of both CPCI and CSA certification programs, and concluded the CPCI program was superior. “The best thing that’s happening now is our specification is getting into architects specifications,†Hall says. “They’re saying that ‘In order to bid on this project you must be a CPCI member.’â€

Sustainable design

Finally, CPCI is also focused very intently on the issue of sustainable design. CPCI itself has three committees, and one of them is a sustainable committee – an inclusion which reflects its importance to the Institute. “One of the things we said when we started this whole idea of trying to be a better corporate citizen and a more sustainable manufacturer is – first of all – it’s the right thing to do,†Hall says. “Now it’s very easy to say that, but you also need to pay for it. So that’s what we’ve been doing.â€

A couple years ago they put their money where the mouth is when they conducted a lifecycle assessment on their product. This entailed going into precast plants and tracking every piece of material that entered the plant until the actual product left.  “That showed us everywhere that we had some type of effect on the environment, and actually helped us come up with ways to negate those effects,†Hall says.

CPCI has also introduced a Green Plant program that measures environmental performance standards such as dust control, water management, chemical management and noise control, as well as energy use, material use, and transportation costs. “These are the things we’re going to be tracking and there’s going to be a pass and fail grade,†Hall explains. At first, CPCI member plants will join that program on a volunteer basis. Within a couple of years, however, Hall says it will become a mandatory part of the CPCI certification.

“We figured we’d better walk before we run and get our members and plants used to collecting this information before we made it part of the plant certification program,†Hall explains. “The focus on sustainable manufacturing has really come around at CPCI, though. I would think that probably most of the members will volunteer within the first year. The response we’ve had so far is absolutely great.â€

To learn more about CPCI, their role in the precast concrete industry, and their various initiatives, visit http://www.cpci.ca

My questions to you are quite basic. Things like:

• Market size of precast concrete industry in Canada

• Any information you can give me regarding inserts and lifting systems used here in Canada

• Manufacturers of lifting devices here in Canada, • Market size

• Regulations, standards, laws regarding lifting devices

• Insurance requirements for precast concrete, and especially, lifting devices and systems

• Name of someone in Canada I can talk to about the insert and lifting systems for precast concrete industry in Canada.

Comments are closed.