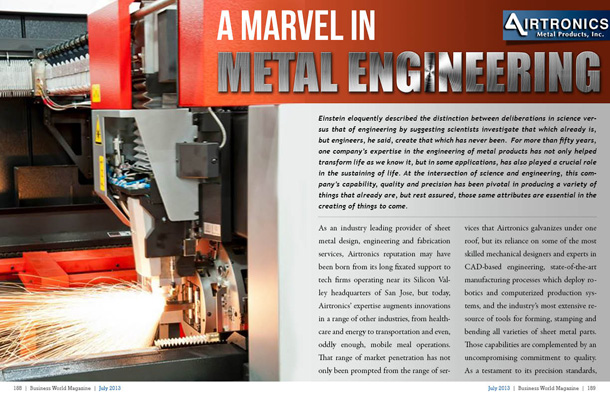

A Marvel in Metal Engineering

Einstein eloquently described the distinction between deliberations in science versus that of engineering by suggesting scientists investigate that which already is, but engineers, he said, create that which has never been. For more than fifty years, one company’s expertise in the engineering of metal products has not only helped transform life as we know it, but in some applications, has also played a crucial role in the sustaining of life. At the intersection of science and engineering, this company’s capability, quality and precision has been pivotal in producing a variety of things that already are, but rest assured, those same attributes are essential in the creating of things to come. Â

As an industry leading provider of sheet metal design, engineering and fabrication services, Airtronics reputation may have been born from its long fixated support to tech firms operating near its Silicon Valley headquarters of San Jose, but today, Airtronics’ expertise augments innovations in a range of other industries, from healthcare and energy to transportation and even, oddly enough, mobile meal operations. That range of market penetration has not only been prompted from the range of services that Airtronics galvanizes under one roof, but its reliance on some of the most skilled mechanical designers and experts in CAD-based engineering, state-of-the-art manufacturing processes which deploy robotics and computerized production systems, and the industry’s most extensive resource of tools for forming, stamping and bending all varieties of sheet metal parts. Those capabilities are complemented by an uncompromising commitment to quality. As a testament to its precision standards, more than ten years ago, Airtronics was the first enterprise in the valley to qualify for ISO9001 certification. Its quality managements systems have also earned ISO13485 certification (essential in the manufacturing of healthcare devices). Airtronics can effectively respond to the most complex of design specs or volume production requirements, and its finishing services extend from painting, plating and silk screening to electromechanical assembly and quality assurance testing.

From Sunnyvale to Silicon Valley

From the very launch of Airtronics in 1961, which initially operated from an 8,000 square-foot facility in Sunnyvale California, the company became a pioneer in producing metal parts that uniquely catered to needs in the electronic industry. It went through several changes in ownership early on, but in 1981, John Richardson purchased the company and provided the leadership crucial to transitioning Airtronics into all it is today. Richardson was a former executive with Fairchild Semiconductor, the company widely credited with inventing the integrated circuit as well as other technologies which help spur the advance of the computer industry. Richardson astutely recognized that industry would need a source for metal fabrication services and Airtronics was evolved to seize upon those opportunities. The company continually grew and eventually moved into a 65,000 square-foot facility located in an enterprise zone south of downtown San Jose.

Vice President Mike Nevin credits the company’s growth to Airtronics’ inordinate ability to devise efficient and cost-effective solutions for transforming a concept into a manufacturable component. “We work closely with our customers in the design process,†explains Nevin. “Most companies already have their own engineers and they know what they want. The key is determining whether it can be built more economically. They may come up with an initial model, but we can make suggestions to help make it more manufacturable. In other cases, the customer may only have a concept and we’ll create the model, design for manufacturability from the beginning. We can make virtually anything, but the challenge is finding the way to make it as affordable as possible for the customer without compromising on quality.†Airtronics has been helping its customers overcome manufacturing challenges for more than fifty years, and to be sure, over the decades, it has participated in the creating of innovations which have profoundly impacted life.

Precision Products

Parts for semiconductors, consumer electronics, network infrastructure, as well as cabinets, enclosures and racks – all of these are among the products produced by Airtronics. For a long time, so much of Airtronics’ efforts were precariously tied to the tech industry, making it particularly susceptible to fluctuations in that industry. When the tech bubble burst, Airtronics was able to mitigate the impact because it had foreseen the dangers of being too dependent on any one industry. It had already begun investing in equipment that would empower it to produce new parts for application in other industries; in fact, Airtronics was among the first enterprises to capitalize on efficiencies of new CNC equipment. Throughout the 90s, services evolved to offering the range of engineering and design support, as well as the finishing, assembling and packaging necessary to provide customers with turnkey solutions. In 2004, Richardson sold Airtronics to its own upper management team comprised by Director of Engineering Jim Ellis, Director of Manufacturing Fermin Rodriguez, Director of Finance & Administration Diane Neff, and Director of Sales & Marketing/CEO Jeff Burke.

Burke has been with Airtronics for 20 years, and under his leadership today, Airtronics has greatly diversified its market penetration, but continues to provide support to innovations of industry. In the healthcare industry, Airtronics is a critical supplier of parts used in kidney dialysis equipment. For people afflicted by weakened or failed kidneys, these devices are critical to keeping alive. Airtronics is also providing components essential to EKSO Bionics, a company which has engineered a kind of exoskeleton (wearable robotic system) that enables paraplegics, stroke victims or anyone whose lost use of the lower limbs to experience a new means of mobility and capability. As Nevin says, “Our staff takes a lot of pride in their work because they know their doing something that genuinely helps people, but that also helps drive their commitment to quality.â€

Airtronic is also a key supplier to Tesla Motors who is redefining capabilities in the realm of automotive transport. Airtronics additionally produces the parts vital in constructing the charging stations on which Tesla vehicles depend. Bloom Energy is also among the companies who rely on Airtronics. Bloom has patented a revolutionary new power generation system that deploys solid oxide fuel cell technology. As opposed to dirty combustion, the fuel cells use an electro-chemical process of energy generation which is not only reliable and more affordable than conventional systems, but is also environmentally-friendly. Yet, for all the science and sophistication in its support to these industries, Airtronics has further evolved by creating its own line of products as evidenced by Metal Gourmet. This is a new division which specializes in the production of mobile food carts and trailer systems essential in the food service trade.

By expanding on its own new product lines, and continually seeking means to improve quality and manufacturability of products for its existing clients, Nevin says Airtronics is positioned for further growth and continuance of the company’s legacy for innovation and integrity.

Nevin doesn’t speak glibly about the importance of quality and customer service because he has, too often, witnessed the impact that occurs when national companies heavily rely on sourcing from foreign manufacturers. For all the talk of manufacturing returning to the US due to increases in foreign labor, transportation and quality denigration, Nevin says there are many companies who still turn to foreign producers. “It is tough to compete when some potential customers are more concerned with costs than quality,†he says, adding that savings, for some, outweigh the inconveniences and inconsistencies incurred from foreign outsourcing. Nevin says that awareness compels everyone at Airtronics to maintain the best relationship possible with existing customers, which ultimately prompts quality, delivery on assurances, design cooperation and collaboration, and committed response to customer needs. As Nevin says, “We want our relationship to be so good that our customers will actually want to resist sending their business offshore.â€

For more information, please visit their website at: Â Â Airtronics Metal Products, Inc.